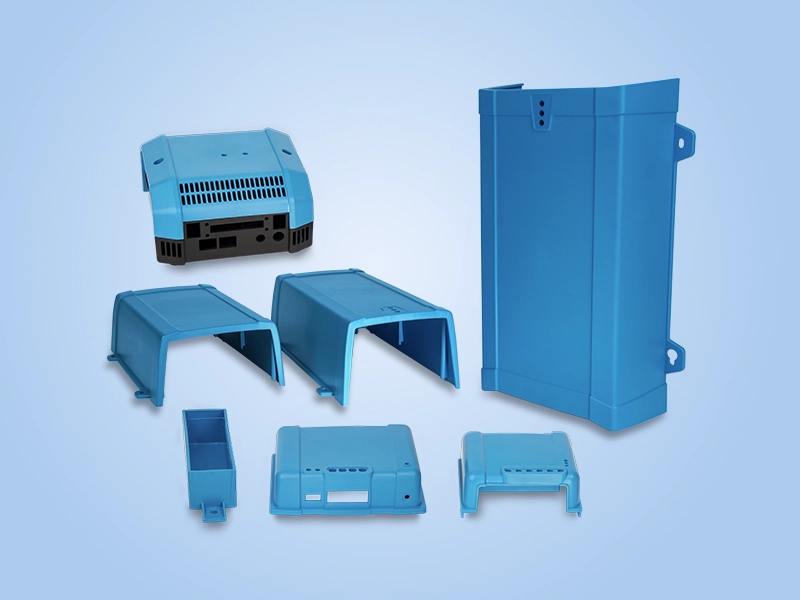

PLASTIC INJECTION MOULDED COMPONENTS

As an ISO-certified organization, we uphold a robust Quality Management System to deliver consistent,

high-quality products on time, every time.

Our customers choose us for reliability and precision, and we’re committed to delivering value consistently. With a vision to become the outsourcing partner of choice for mechanical parts to leading global

manufacturers, we are continuously investing in state-of-the-art equipment and skilled personnel to better serve your needs.

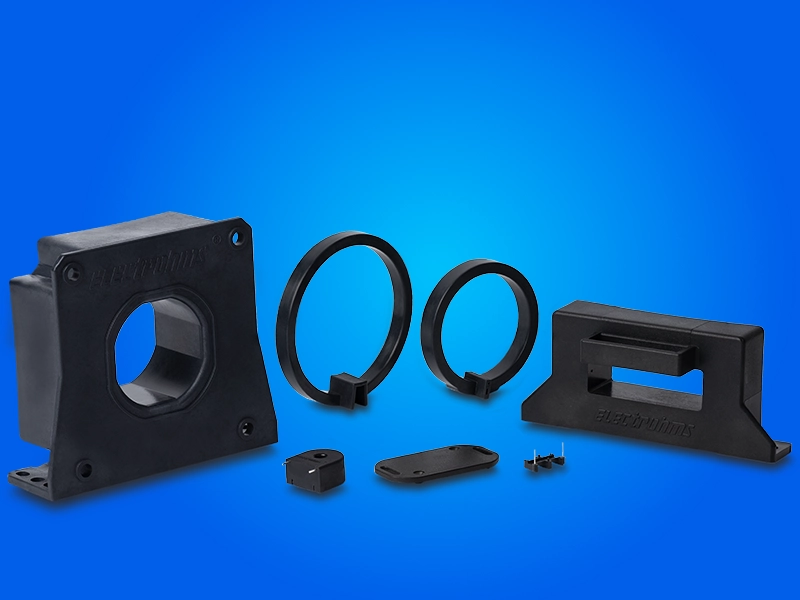

INSERT MOULDED COMPONENTS

Multitek manufactures Insert moulded components using advanced manufacturing process to create durable and high-precision components by encapsulating metal or plastic inserts within a molded plastic structure. This process involves placing preformed inserts—such as threaded bushings, electrical contacts, or reinforcement structures—into a mold before injecting molten plastic around them.

The technology ensures strong bonding between the insert and the plastic, enhancing product strength,

reducing assembly time, and improving reliability. Insert moulding is widely used in industries like automotive, electronics, medical devices, and aerospace for producing complex, lightweight, and high-performance components with excellent dimensional accuracy and consistency.

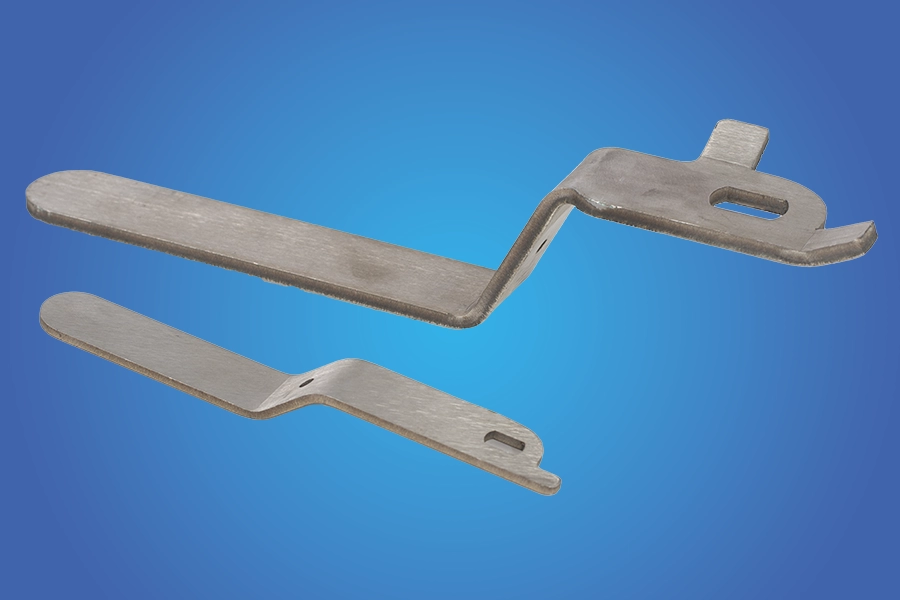

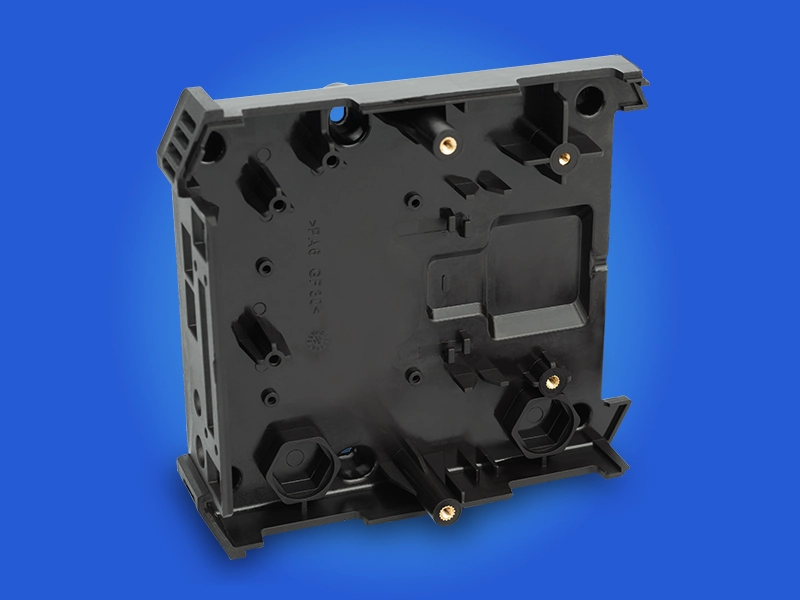

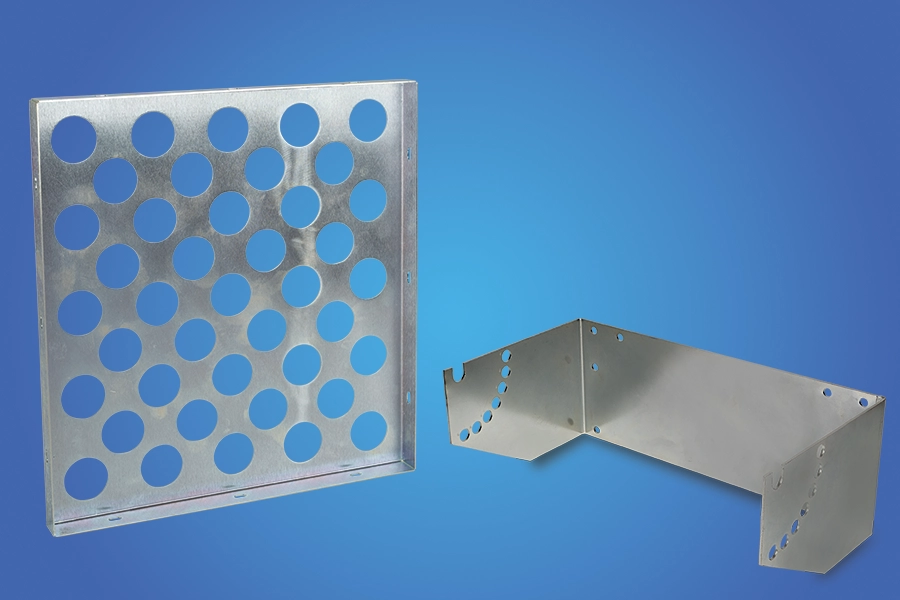

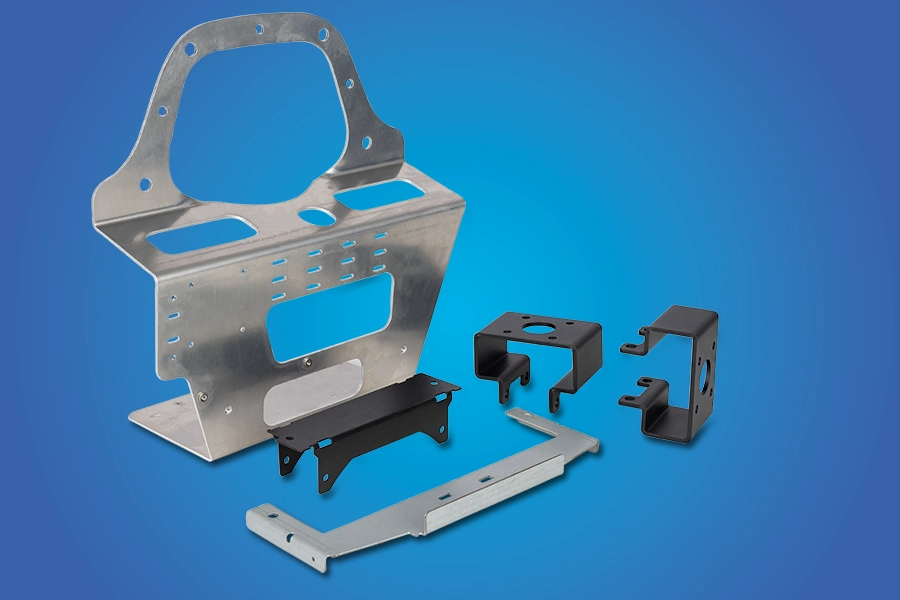

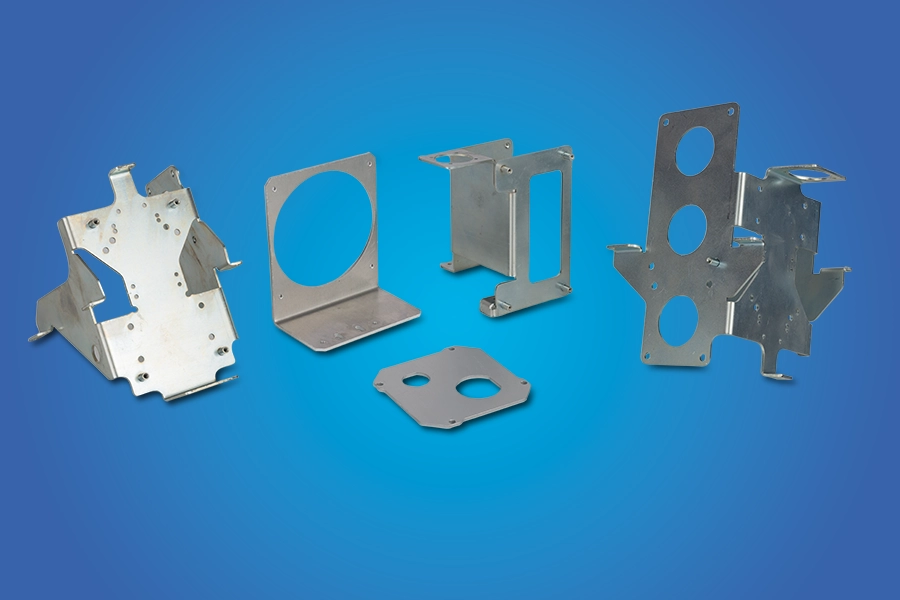

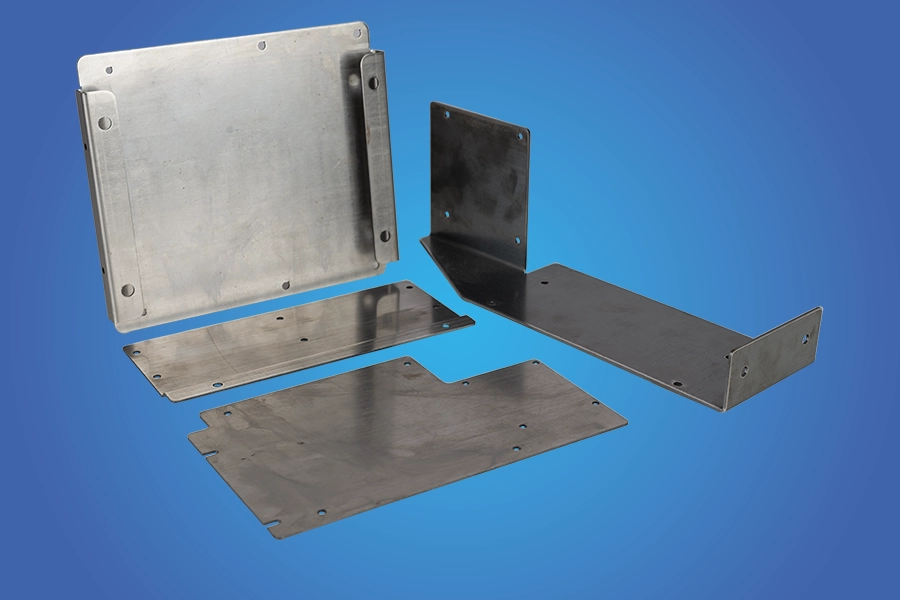

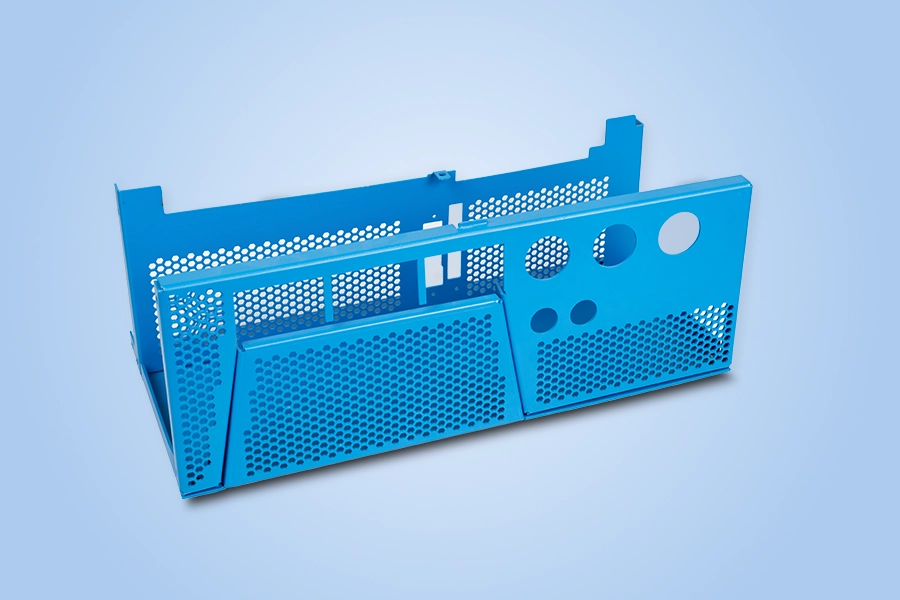

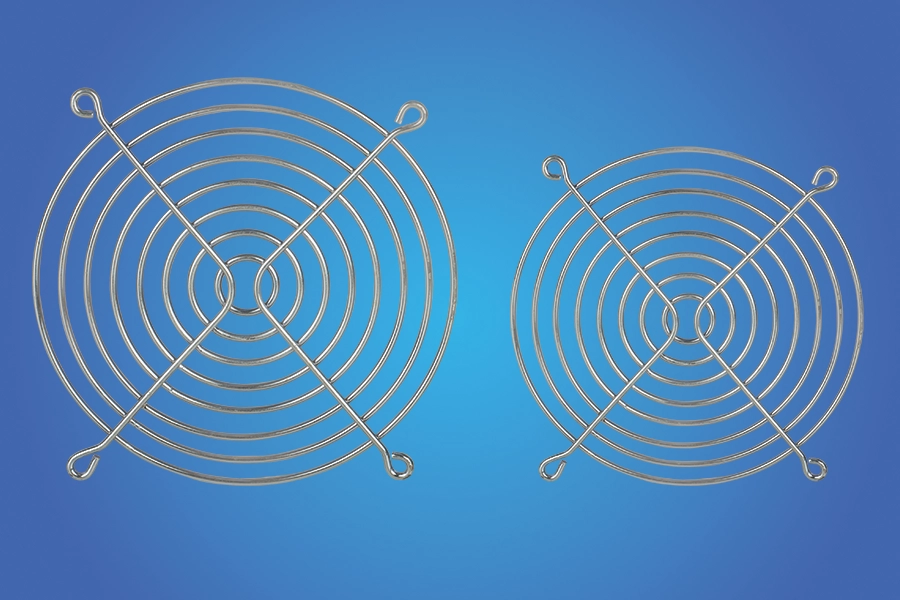

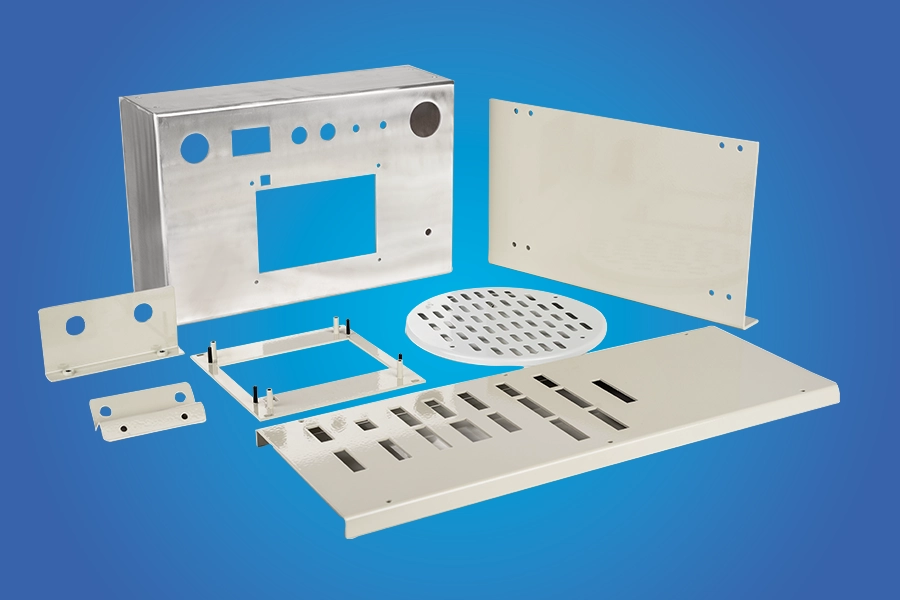

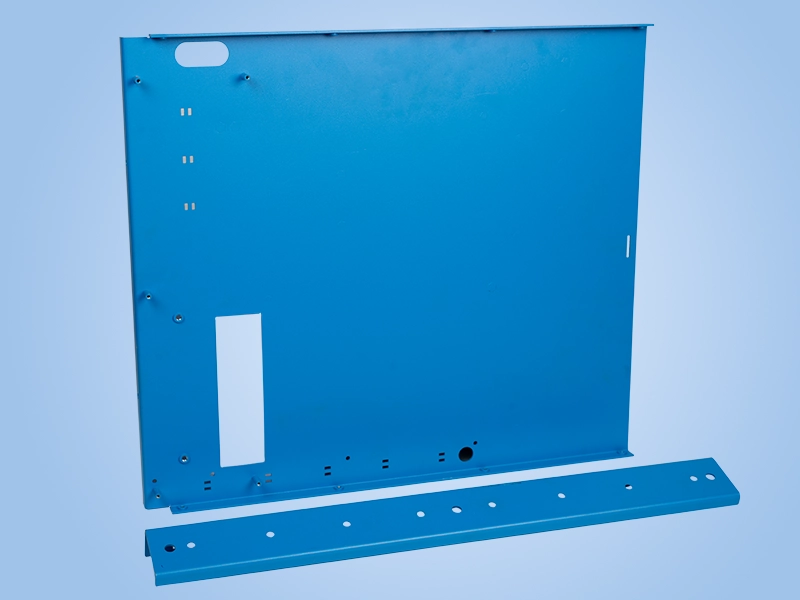

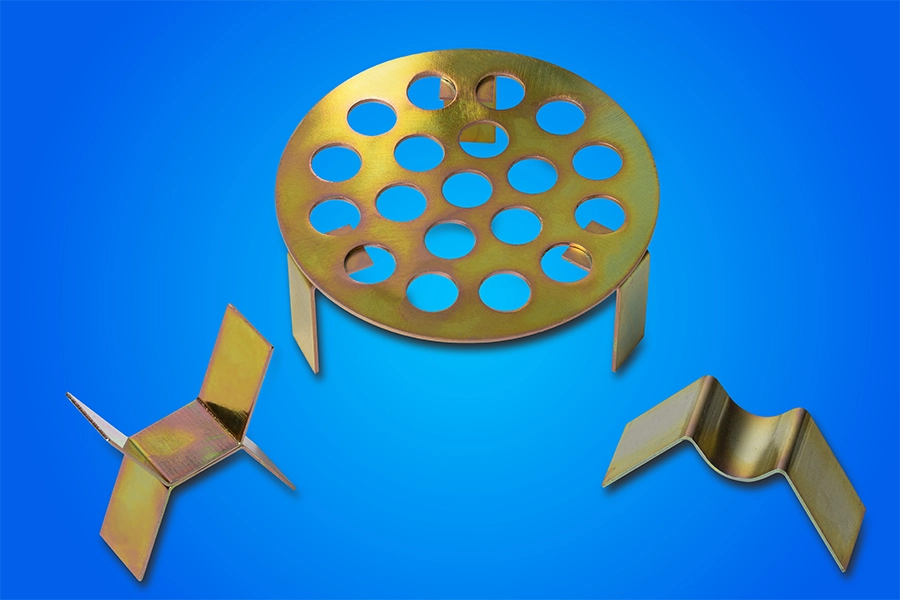

SHEET METAL FABRICATED COMPONENTS

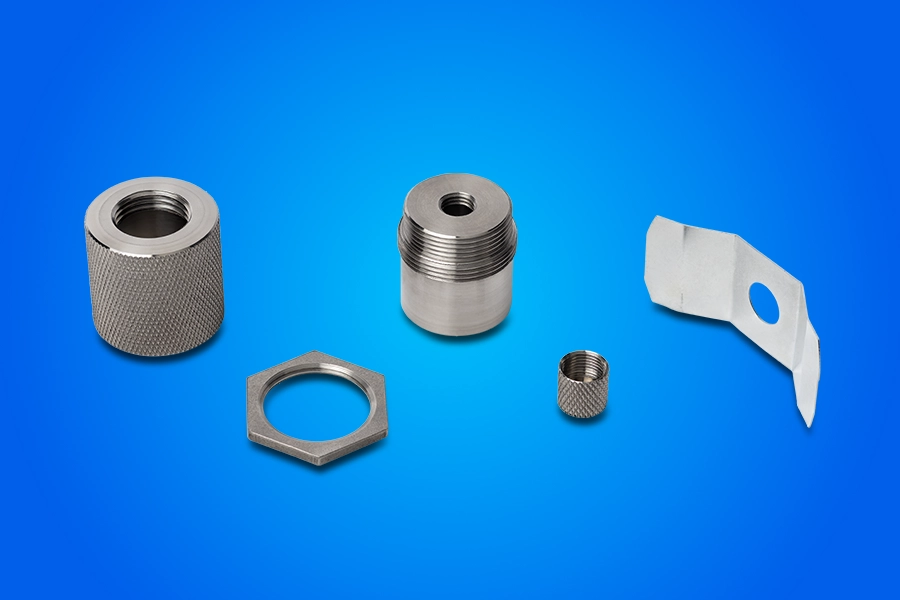

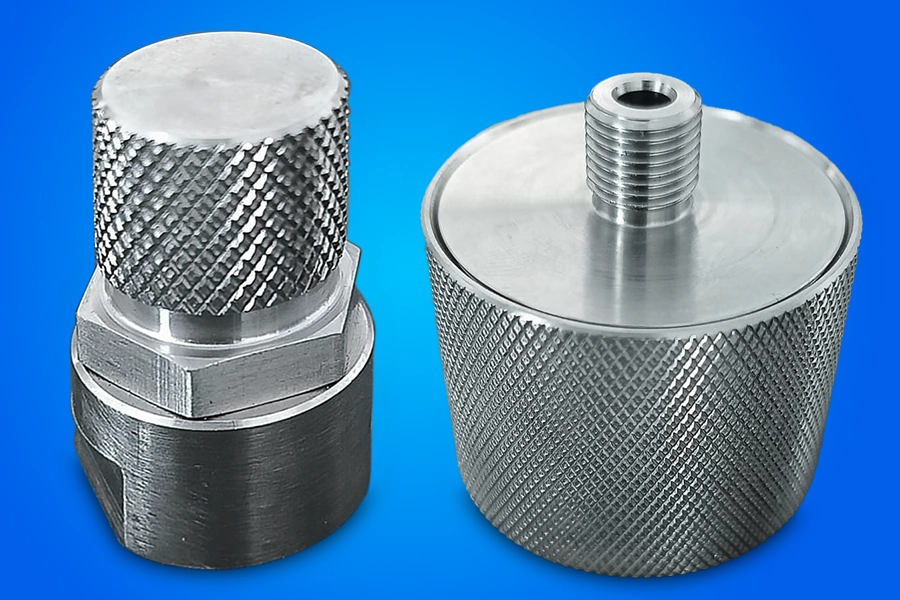

PRECISION MACHINED COMPONENTS